Research background

As the ultimate form of drive for future electric vehicles, the in-wheel motor system is conducive to improving the mobility and reaction speed of the vehicle, making the vehicle better adapted to complex terrain and battlefield environments, and optimizing the design of the vehicle's independent suspension, so that the in-wheel motor can be applied to all types of modern military vehicles. It is conducive to improving the energy efficiency and range of the vehicle, reducing the friction and shock among transmission components, lowering the vibration and noise, and improving the stealthiness when carrying out the mission.

Key technologies & Innovations

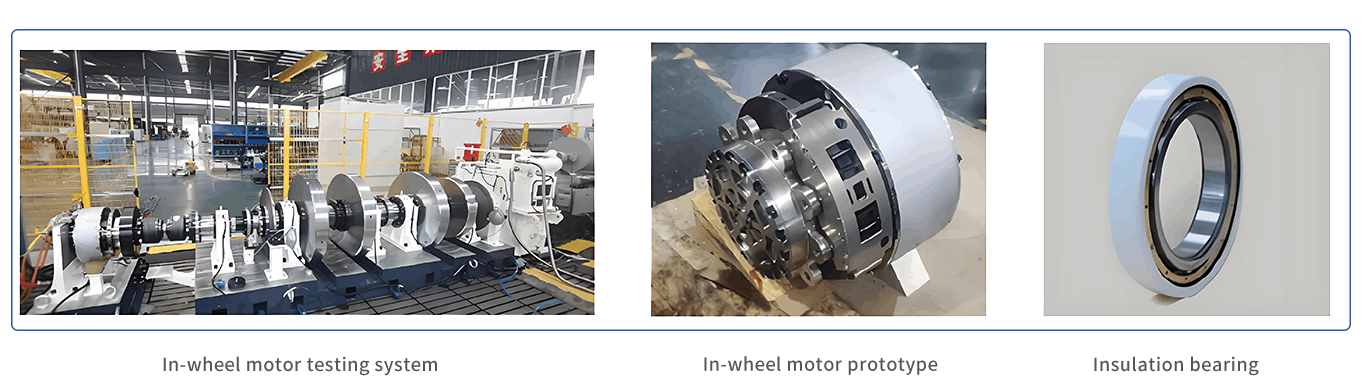

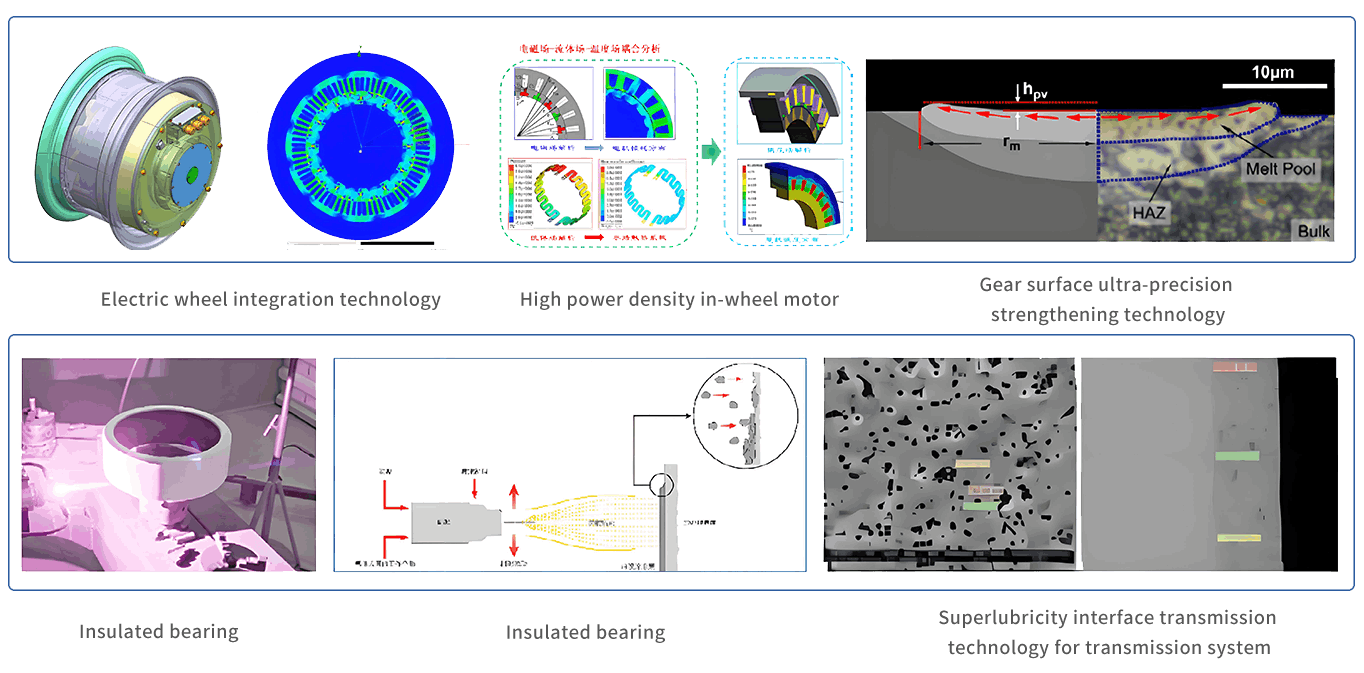

1.Structure-function fusion of integrated in-wheel motor, torque density≥70Nm/kg;

2. New materials, machining process and structure design of in-wheel motor, maximum efficiency≥97%, maximum speed≥9000r/min;

3. Transmission interface superlubricity technology, friction coefficient is reduced by an order of magnitude;

4. Ultra-precision laser strengthening technology, gear surface hardness > 1000HV;

5. Insulated bearing technology, DC breakdown voltage≥5000V.

Advantage

The product is based on the concepts of structure-function fusion and modularization, and therefore offers the advantages of high integration, high torque density, high efficiency, high reliability and low cost.