Research background

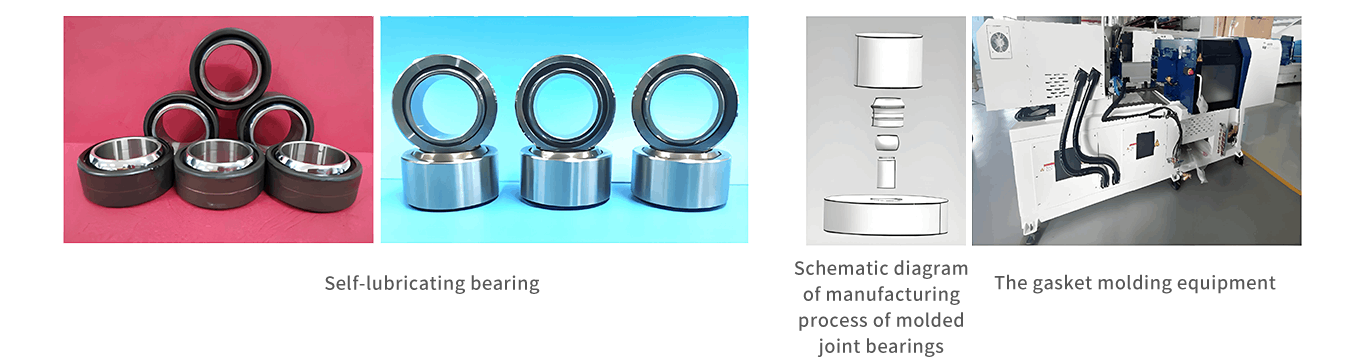

Regarding the issues of uneven materials, fluctuations in friction coefficient, and poor stability of manually attached gaskets in fabric type self-lubricating bearings, molded self-lubricating joint bearings are developed to promote the tech upgrading of China's high-end self-lubricating joint bearings industry, fill the domestic tech gap and break through the foreign tech blockade.

Technical principles

By doing research and development on the design of molded self-lubricating composite materials, the manufacturing process of molded gaskets and self-lubricating joint bearings, to make molded self-lubricating joint bearings with excellent performance.

Advantage

The molded self-lubricating joint bearing has the advantages of high load capacity, long service life, high machining precision, stable performance, and can be customized in any size thickness.

Apply

Aviation self-lubricating joint bearings are widely used in large transport aircraft, helicopters, commercial airliners and other models.

Achievements

The service life of molded joint bearings working under low-speed and heavy load conditions is more than 50% longer than that of similar bearings in foreign countries, which meets the standard of self-lubricating bearings of U.S. military aviation.